Recycled polyester filament has the following advantages:

1. Environmental friendliness

Raw material recycling: The production of recycled polyester filament mainly uses waste polyester bottle chips, waste textiles, etc. as raw materials. By recycling and reprocessing these waste materials, the amount of landfill and incineration has been effectively reduced, the pressure on the environment has been lowered, and non renewable resources such as oil have been saved, as the production of traditional polyester filament relies on petrochemical raw materials.

Reduce energy consumption: Compared to producing polyester filament from crude oil, the production process of recycled polyester filament can save a lot of energy. The energy required for producing recycled polyester filament is only about 20% -30% of that for producing native polyester filament, which helps to reduce carbon emissions and alleviate the global energy crisis.

2. Performance characteristics

Good physical properties: Recycled polyester filament has similar physical properties to native polyester filament, such as high strength, high modulus, and good wear resistance. It can withstand high tensile forces without breaking and is suitable for manufacturing various textiles that require high strength, such as clothing, home textiles, industrial fabrics, etc.

Good chemical stability: It has good resistance to chemical corrosion, can resist the erosion of acidic and alkaline chemicals, and is not easily damaged by chemical reactions. Therefore, it can maintain good performance under different environmental conditions and extend its service life.

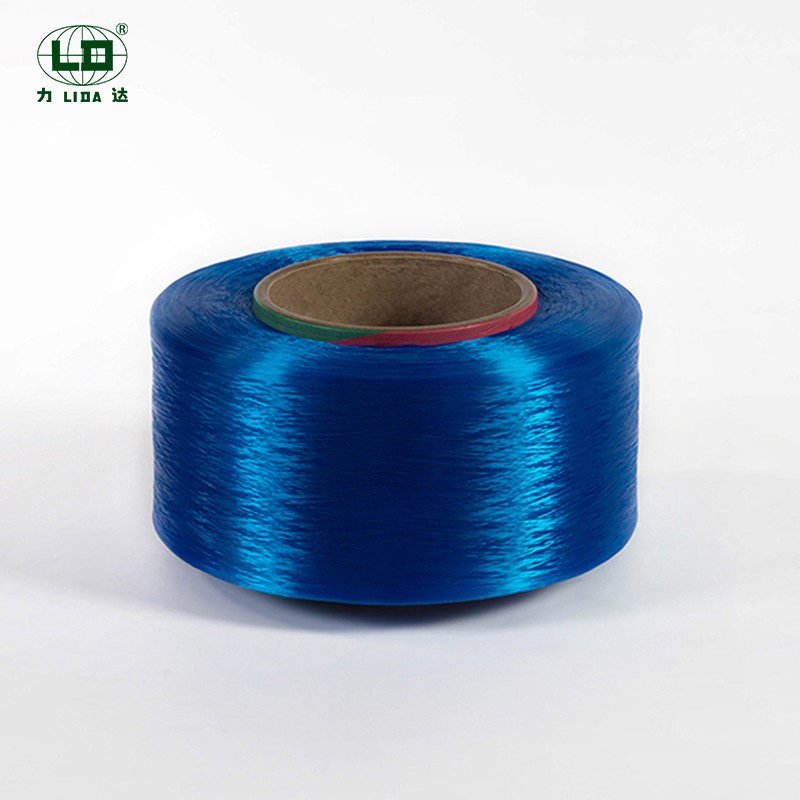

Excellent dyeing performance: Like native polyester filament, recycled polyester filament can be dyed with a variety of colors through various dyeing processes, and the dyed color is bright, strong, and not easy to fade, which can meet the needs of different consumers for textile color and appearance.

3. Economic benefits

Cost advantage: With the continuous development and improvement of recycling technology, the production cost of recycled polyester filament is gradually decreasing. The relatively low prices of raw materials such as discarded polyester bottle chips and reduced energy consumption during the production process make recycled polyester filament have a certain cost competitiveness, especially in large-scale production, where the cost advantage is more obvious.

Industry driven: The development of the recycled polyester filament industry has driven the rise of related industrial chains, such as the establishment of a waste textile recycling system and the development of bottle processing enterprises, creating more employment opportunities and economic benefits, and promoting the development of circular economy.

Recycled polyester filament has significant advantages in environmental protection, performance, and economy, which is in line with the trend of sustainable development and has broad application prospects in the textile industry.