High Tenacity Low Shrinkage Polyester Filament is a specialized synthetic yarn engineered to deliver exceptional strength, dimensional stability, and thermal resistance. Widely used in demanding industrial applications such as tire cord, conveyor belts, industrial fabrics, and reinforcement materials, this filament plays a crucial role in enhancing product durability and performance. This article provides a comprehensive overview of its properties, manufacturing process, advantages, applications, and selection criteria, helping manufacturers and buyers make informed decisions.

High Tenacity Low Shrinkage Polyester Filament is a high-performance yarn produced from polyethylene terephthalate (PET). Unlike conventional polyester filament, it is engineered to achieve significantly higher tensile strength while maintaining minimal thermal shrinkage under heat exposure.

These characteristics make it especially suitable for industrial and technical applications where dimensional stability, load-bearing capability, and long-term reliability are essential. According to industry references such as High Tenacity Low Shrinkage Polyester Filament, this material is designed to withstand harsh mechanical and thermal conditions.

| Property | Description |

|---|---|

| High Tenacity | Provides superior tensile strength for load-bearing applications |

| Low Thermal Shrinkage | Maintains dimensional stability under high temperatures |

| Excellent Fatigue Resistance | Performs reliably under repeated stress and dynamic loads |

| Chemical Resistance | Resists oils, solvents, and most industrial chemicals |

| Uniform Structure | Ensures consistent performance in weaving and coating processes |

These properties collectively enable manufacturers to create industrial products with longer service life and improved safety margins.

The production of High Tenacity Low Shrinkage Polyester Filament involves advanced spinning and drawing techniques designed to align molecular chains and reduce internal stress.

This process ensures that the filament meets strict industrial performance requirements.

| Feature | High Tenacity Low Shrinkage | Standard Polyester Filament |

|---|---|---|

| Tensile Strength | Very High | Moderate |

| Thermal Shrinkage | Low | Higher |

| Industrial Suitability | Excellent | Limited |

| Service Life | Long | Shorter |

In these applications, low shrinkage ensures structural integrity during heat processing and long-term use.

Using High Tenacity Low Shrinkage Polyester Filament offers multiple benefits:

When selecting a suitable filament, consider the following factors:

High Tenacity Low Shrinkage Polyester Filament is typically tested according to international standards for:

Consistent testing ensures performance stability across different production batches.

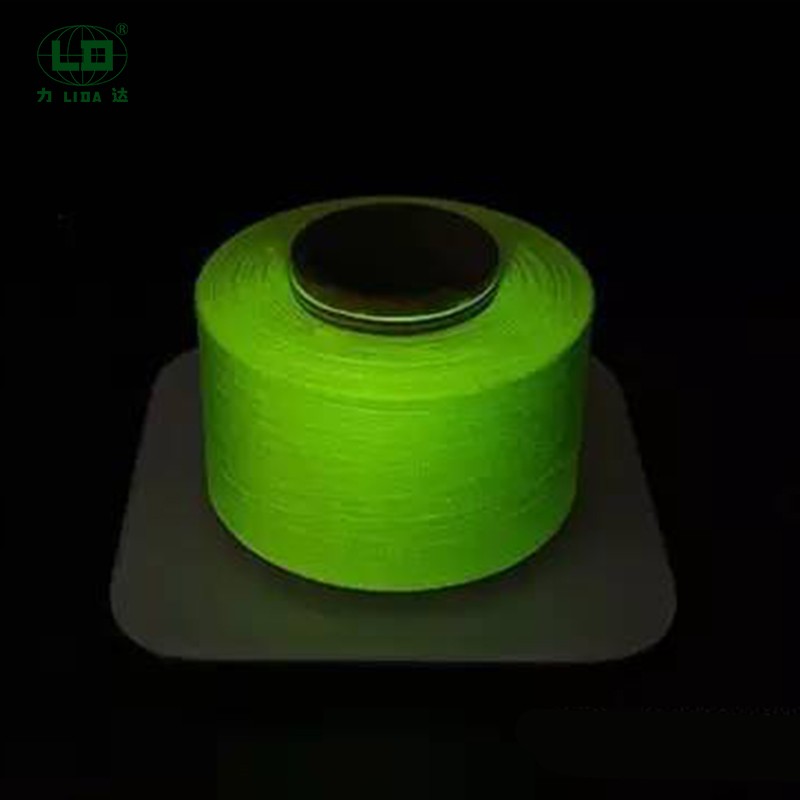

LIDA has established itself as a reliable manufacturer of High Tenacity Low Shrinkage Polyester Filament by focusing on advanced production technology, strict quality management, and customer-oriented solutions. With a strong commitment to innovation and consistency, LIDA supports a wide range of industrial and technical textile applications worldwide.

Its enhanced molecular orientation results in higher tensile strength and improved performance under stress.

Low shrinkage prevents deformation during heat processing, ensuring dimensional accuracy and product reliability.

Yes, it is widely used in rubber-based products such as tires and conveyor belts due to its thermal stability.

Most manufacturers, including LIDA, offer customized specifications to meet different industrial requirements.

High Tenacity Low Shrinkage Polyester Filament is an indispensable material for modern industrial textiles, offering unmatched strength, stability, and durability. Choosing the right supplier and specification can significantly enhance product performance and lifecycle value.

If you are looking for a reliable source of high-quality polyester filament tailored to your industrial needs, LIDA is ready to support your projects. Contact us today to learn more about customized solutions and technical support.