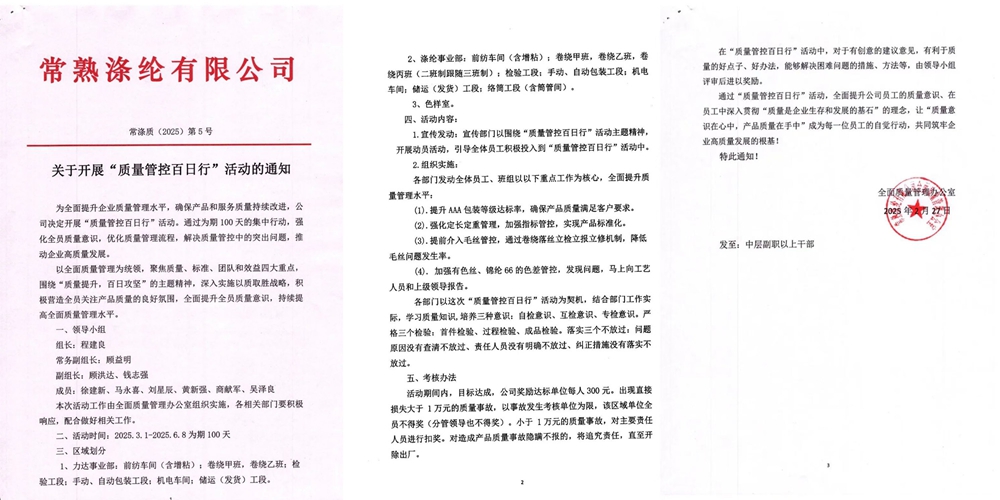

Since the launch of the "Quality Control Hundred Day Campaign" on March 1, 2025, Changshu Polyester has anchored its comprehensive quality management goals with the theme of "Quality Improvement, Hundred Day Campaign", and tightened the quality "safety valve" through multiple dimensions and measures. The data shows that the number of complaints from the two business units during the event has significantly decreased compared to last year, and there has been a significant improvement in quality awareness and process optimization.

Leaders attach great importance to it

Chairman and General Manager Cheng Jianliang has held multiple meetings to deploy work, clarify the relevant content of the "Quality Control Hundred Day Tour" activity, and require the Quality Office and two business units to implement relevant matters, laying the organizational foundation for the "Quality Control Hundred Day Tour" activity.

Develop activity plan

The Quality Control Office has developed a "Quality Control Hundred Day Tour" activity plan, which clarifies the activity time, divides the activity areas and units, and sets key goals: focusing on improving the compliance rate of AAA packaging grade, strengthening fixed length and weight management, and intervening in wool control in advance, breaking down indicators, so that each position has a quality "responsibility field".

Hold monthly quality meetings

Hold monthly quality analysis meetings to analyze the existing problems and customer complaints from the previous month, discuss improvement plans on site, and track their implementation.

Conduct team meetings

Each inspection and packaging team insists on holding daily pre shift meetings, weekly meetings, and monthly summary meetings to systematically review work processes, clarify key tasks for the day, emphasize recent key issues, and integrate quality detail control into every work node to ensure that no potential problems are missed.

Spot check product quality

The Quality Assurance Office strictly controls product quality through daily on-site inspections, weekly spot checks on auxiliary materials and finished products, and monthly spot checks on finished yarn and weight to prevent defective products from entering the hands of customers.

Through the "Quality Control Hundred Day Campaign", there has been some improvement in product quality. However, complaints caused by human factors such as packaging the wrong wire, misreading the color of the tube, and attaching the wrong outer packaging label have occurred from time to time. Although the campaign has ended, we still cannot afford to slack off on quality issues.

Quality is the lifeline of enterprises, and Changshu Polyester will take the "Quality Control Hundred Day Tour" as an opportunity to solidify the experience and practices in the activities into a long-term mechanism, continuously build a solid foundation of quality, and provide customers with better products.