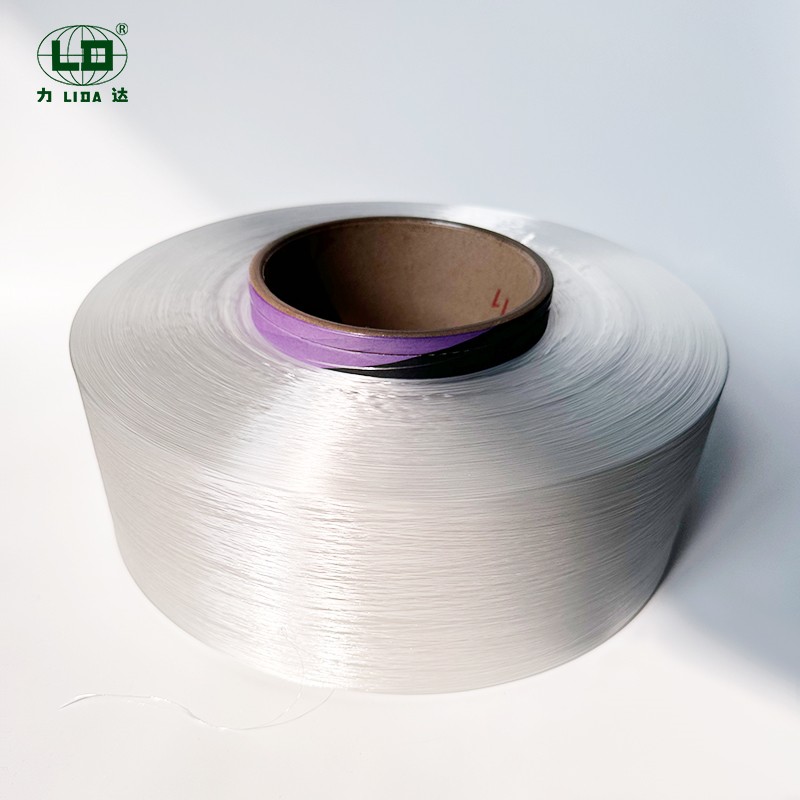

Anti Fire Filament Yarn Nylon 6 is a high-performance fiber modified with flame retardancy on the basis of ordinary nylon 6 filament. Its core advantages include flame retardancy, mechanical stability, processing adaptability, and environmental compliance. At the same time, it retains the basic characteristics of nylon 6 and is suitable for various scenarios such as B2B industry, electronics, and automobiles. The following are specific characteristics:

1、 Core flame retardant performance (safety core)

Flame retardant rating and self extinguishing: Passed UL94 V0/V1 level (commonly 0.8-1.6mm thickness), vertical combustion and other tests, difficult to ignite in the event of fire, and quickly self extinguishing after leaving the fire; The halogen-free system can suppress droplets and reduce the risk of secondary ignition.

Oxygen Index (LOI) improvement: Pure nylon 6 has an LOI of about 20% -22%, and fire-resistant filament can reach 28% -35%, making it more difficult to ignite in air environments.

Low smoke and low toxicity: The halogen-free formula (phosphorus based, nitrogen based, metal hydroxide) does not release hydrogen halides when burned, and the smoke density and toxic gas content are significantly lower than those of halogenated types, meeting environmental and safety standards such as RoHS and REACH.

Enhanced thermal stability: The structure remains stable at high temperatures (such as 100-120 ℃ for a long time) and is not easily softened or deformed, making it suitable for industrial high-temperature conditions.

2、 Mechanics and Physical Properties (Application Fundamentals)

Strength and toughness balance: The filament shape retains high tensile strength, impact resistance, and wear resistance. After fiber modification, the rigidity/strength can be increased by 50% -100%, making it suitable for load-bearing and repeated friction scenarios.

Excellent dimensional stability: The combination of filament structure and modification (such as fiberglass) significantly reduces the molding shrinkage rate (about 1.5% → 0.5%), reduces warpage, and is suitable for precision components and textile shaping.

Basic characteristics retained: Inheriting the self-lubricating, oil resistant, chemical resistant (weak acid, weak alkali, solvent), electrical insulation properties of nylon 6, suitable for electronic, automotive and other working conditions.

Heat resistance and aging resistance: Long term use temperature is 100-120 ℃, and some modified models can withstand short-term temperature up to 150 ℃; UV resistant modification can enhance outdoor durability.

3、 Processing and molding adaptability (production friendly)

Compatible molding process: Suitable for extrusion spinning, injection molding, blow molding, etc., can be made into long silk, multifilament, monofilament, used for textiles, cables, components, etc.

Good textile processability: Long filaments have excellent spinnability and can be woven and knitted into fabrics, suitable for protective clothing, industrial filter materials, automotive interiors, etc. They have good dyeing properties and stable colors.

Large customization space: It can composite glass fiber, toughening agents, anti-static agents, etc., while meeting the composite needs of flame retardancy, reinforcement, anti-static, etc., suitable for complex industrial scenarios.

4、 Environmental Protection and Compliance (Key for Export and Certification)

Zero halogen environmental protection: It does not contain halogens such as chlorine and bromine, and burns non-toxic hydrogen halides, which meets the environmental access requirements of markets such as Europe, America, Japan, and South Korea.

Certification adaptation: Easy to pass UL, IEC, GB and other flame retardant and safety certifications, helping foreign trade exports and downstream customer project compliance.

Sustainability: Some halogen-free systems are recyclable or have low environmental load, in line with the trend of green supply chain.

5、 Typical application scenarios

Electronic appliances: connectors, coil frames, wire harness sheaths, insulation components (flame retardant+insulation+temperature resistance).

Automotive industry: engine peripherals, interior fabrics, piping (oil resistant+flame retardant+size stable).

Industrial protection: flame retardant protective clothing, gloves for high temperature conditions, conveyor belts (wear-resistant+flame retardant+anti droplet).

Rail transit/aviation: interior fabrics, cable wrapping (low smoke and low toxicity+flame retardant+lightweight).